Advanced Pipeline Welding Inspection: Techniques for Detecting Problems

Advanced Pipeline Welding Inspection: Techniques for Detecting Problems

Blog Article

Best Practices for Pipe Welding Inspection: Strategies, Requirements, and Treatments to Attain Top Quality Guarantee and Conformity

Effective pipe welding examination is vital for making certain the honesty and safety and security of vital infrastructure. Understanding the complexities included in each phase of examination is essential to achieving compliance and dependability in pipeline systems.

Importance of Welding Assessment

The integrity of bonded joints is critical in guaranteeing the security and integrity of pipeline systems. Appropriate welding strategies and comprehensive inspection procedures are vital to stop failings that can result in disastrous cases, ecological damage, and loss of life. Pipeline Welding Inspection. Welding assessment serves as a safety net, identifying problems such as cracks, porosity, and incomplete combination prior to they intensify into significant issues

Furthermore, pipeline systems typically operate under high pressure and extreme conditions, making the quality of welds much more important. Regulatory compliance is an additional significant facet, as numerous criteria determine the quality control procedures that should be abided by in pipe construction and maintenance. Failure to conform can lead to economic losses and lawful implications.

The role of welding inspection extends past plain confirmation of handiwork; it incorporates the assurance of long-term functional stability. This entails a systematic approach that consists of not only visual evaluations however also advanced non-destructive screening techniques. Eventually, reliable welding inspection is an investment in the durability and security of pipe systems, ensuring they operate as meant while lessening dangers connected with product deficiencies.

Key Evaluation Strategies

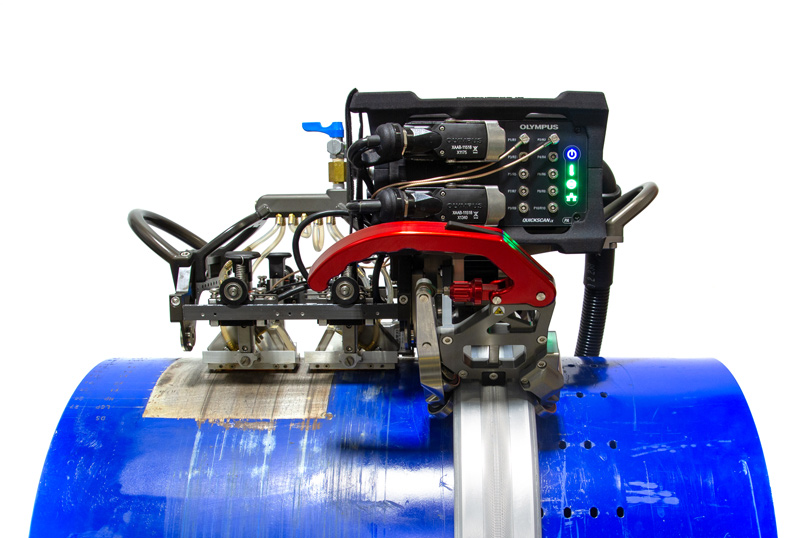

Aesthetic assessment, frequently the initial line of protection, permits the recognition of surface issues such as splits, damages, and porosity. Ultrasonic testing employs high-frequency acoustic waves to detect inner defects, supplying a thorough assessment of weld honesty. This non-destructive technique is particularly reliable for determining discontinuities that may not be visible on the surface area.

Radiographic testing entails making use of X-rays or gamma rays to generate photos of the welded joint, exposing internal flaws. This method offers in-depth understandings but may call for customized tools and safety and security factors to consider. Finally, magnetic fragment screening works for identifying surface and near-surface interruptions in ferromagnetic products, using magnetic fields and great iron particles.

Industry Criteria and Rules

Compliance with sector criteria and laws is important for ensuring the high quality and safety of pipeline welding evaluations. These requirements supply a structure for ideal techniques in welding procedures, materials, and inspection techniques, enabling organizations to reduce issues and improve the honesty of pipeline systems. Secret bodies such as the American Society of Mechanical Designers (ASME), the American Welding Culture (AWS), and the International Company for Standardization (ISO) set forth guidelines that are widely identified and adopted within the sector.

In the USA, policies from the Pipe and Hazardous Products Security Administration (PHMSA) govern the safety and security of pipe operations, mandating extensive examination procedures. These criteria not just serve to safeguard public safety and security and the setting yet likewise make sure conformity with contractual and legal obligations. Adherence to the pertinent codes, such as ASME B31.3 visit this web-site for procedure piping, is important for maintaining functional effectiveness and governing compliance.

Additionally, constant updates and alterations to these requirements mirror technological innovations and advancing sector techniques, emphasizing the requirement for organizations to stay informed and train personnel appropriately. Eventually, robust conformity with recognized criteria fosters count on and integrity in pipe facilities, safeguarding both stakeholders and possessions.

Reliable Examination Procedures

Efficient inspection treatments are crucial for determining possible issues in pipe Full Report welds and ensuring the general honesty of the system. A methodical approach to examination encompasses a number of crucial phases, consisting of pre-weld, in-process, and post-weld examinations. Each phase plays a crucial duty in keeping quality control.

During pre-weld assessment, it is vital to review the products and joint arrangements, guaranteeing compliance with job specifications. In-process inspections entail keeping track of welding strategies and specifications, such as warmth input and take a trip rate, to avoid flaws from occurring. This phase permits real-time changes to welding techniques.

Post-weld assessments consist of non-destructive testing (NDT) strategies like radiography, ultrasonic screening, and magnetic fragment testing. These techniques assist find internal and surface defects that can jeopardize the pipe's performance. Paperwork of all examination activities is paramount, offering a traceable record that supports conformity with industry requirements.

Training and accreditation of inspection employees further improve the performance of these procedures. By sticking to an organized evaluation method, companies can alleviate risks, make certain conformity, and eventually deliver pipelines that meet rigorous security and efficiency demands.

Common Obstacles and Solutions

Pipeline welding examination provides several typical challenges that can influence the high quality and safety and security of the final item. One considerable obstacle is the irregularity in welding strategies and products, which can result in irregular weld quality. To resolve this, it is vital to establish standard treatments and training for welders, guaranteeing an pop over to this web-site uniform strategy throughout tasks.

Environmental aspects, including temperature level and humidity, can also affect the welding process, potentially causing fractures or incomplete combination. Implementing regulated settings and sticking to pre-weld treatments can alleviate these risks.

Conclusion

Finally, the execution of best methods for pipe welding inspection is crucial for guaranteeing high quality guarantee and conformity with sector standards. An extensive method, including numerous techniques such as aesthetic, ultrasonic, and radiographic screening, promotes the identification of issues throughout all phases of the welding procedure. Pipeline Welding Inspection. Adherence to developed guidelines and efficient examination treatments not only enhances the integrity and safety and security of pipeline systems yet additionally reduces risks related to welding problems, consequently promoting overall operational integrity

Compliance with sector standards and regulations is vital for making certain the quality and security of pipeline welding assessments. These criteria offer a framework for finest methods in welding processes, materials, and inspection techniques, permitting companies to decrease issues and boost the stability of pipe systems.In the United States, regulations from the Pipe and Hazardous Materials Safety And Security Administration (PHMSA) govern the security of pipeline procedures, mandating rigorous examination procedures. An organized approach to inspection encompasses a number of essential phases, consisting of pre-weld, in-process, and post-weld evaluations.In final thought, the application of best techniques for pipe welding assessment is necessary for ensuring high quality guarantee and conformity with market requirements.

Report this page